With a Camera and a Drone Audit a Mine Reclamation

Mining companies are often required to restore mine sites to economically usable conditions after extracting minerals. This process, usually referred to as mine reclamation, involves rehabilitation and other processes that minimize the environmental impact of mining. The reclaimed land can be used for agricultural, recreational, commercial, and residential uses. An audit of the reclaimed site by the company or by an agency, may be aided with aerial photography and 3D surface modeling.

The topography of most mining sites makes it difficult for field experts to collect data needed for site mapping. Climbing one quarry face after another to take measurements using GPS systems or other survey tools is a labor-intensive, time-consuming, and dangerous activity. Use of unmanned aircraft systems (UAS) in the mining field has helped to simplify data collection. The drones take high resolution images that are later processed to create accurate 3D descriptions of the mining site. Field experts use close range photogrammetry to produce accurate surface models of mine sites, and reclaimed sites in less time.

The possibilities of UAS use in mining seem endless. With UAS, a mining company can get a more accurate picture of a mine site in less time and without exposing its field experts to dangerous terrain. Photogrammetry enables mining companies and government agencies to generate accurate surface models of sites from digital photographs captured from drones / UAV.

Close-Range Photogrammetry for Mine Reclamation

In this paper: Recent Developments in Close Range Photogrammetry (CRP) for Mining and Reclamation, PhotoModeler Scanner was used to test the suitability of CRP for mining and mine reclamation applications. The presentation describes a number of experiments in measurement techniques for a few different mine sites.

In the first test, photos were taken from a small plane and on the ground. The random photos were used to generate a stereo mesh model of the site. Referenced stereo models were generated from the random photographs taken from this data set. The ground surveys and digital photography provided the ground control required to generate referenced models. It was observed that the aerial photography of the site and the 3D mesh in CAD matched closely, an indicator that realistic and accurate three dimensional descriptions of quarries can be generated from random photographs.

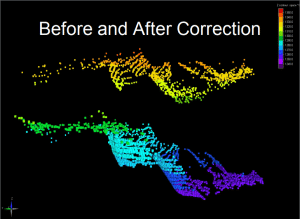

Experiment with lower cost camera

In the second experiment, high quality photographs from consumer-grade cameras were used to model the surface of a mining site. The photographs had points for ground control and orientation. To account for the dis-proportionality of control points and inaccuracy of the Z dimension, the model was corrected by adding tie points at suitable locations. These corrections helped to produce a model that was more accurate and proportional in X, Y, and Z coordinates. The figure below shows the model before and after correction. From this test, it was observed that close-range photogrammetry with less expensive equipment is capable of producing highly accurate surface models required for mining and mine reclamation activities.

It is expensive to hire piloted aircraft to take aerial photos of a mining site. Unmanned aircraft systems have made it easy for mining companies to capture photographs. These unmanned aerial vehicles (UAV) usually carry lightweight cameras that are capable of capturing high quality photographs. Unlike piloted aircraft, UAV offer more flexibility and the total cost is usually lower. The captured images are processed using photogrammetric software to generate accurate scans, volume measurements, or surface models. PhotoModeler for Unmanned Aircraft Systems converts photographs into accurate 3D descriptions, and it is suitable for a broad spectrum of applications including stockpile measurements, mining reclamation, and surveying. This article on UAS / UAV Photography describes how images taken from UAVs are processed using PhotoModeler to generate 3D scans, accurate measurements, and surface models.

Conclusion

To obtain field data to asses and audit reclamation work, mine operators or agencies can employ traditional measurement techniques or photogrammetry. Traditional techniques such as surveys maybe unsuitable for complicated projects, and may not provide as much detail coverage – and usually at higher cost and with longer turn around times. In comparison, photogrammetry is economical and enables mining companies and agencies to obtain accurate surface models quickly. Use of PhotoModeler and UAS in mining enables a company to collect data more easily and accurately and process it to produce high quality 3D models required for mine reclamation activities. In addition, mining companies can use PhotoModeler for UAS for stockpile measurements, ortho-photo mapping, monitoring, modeling structures for modifications, and so on. Here are more applications of PhotoModeler for Unmanned Aircraft Systems.